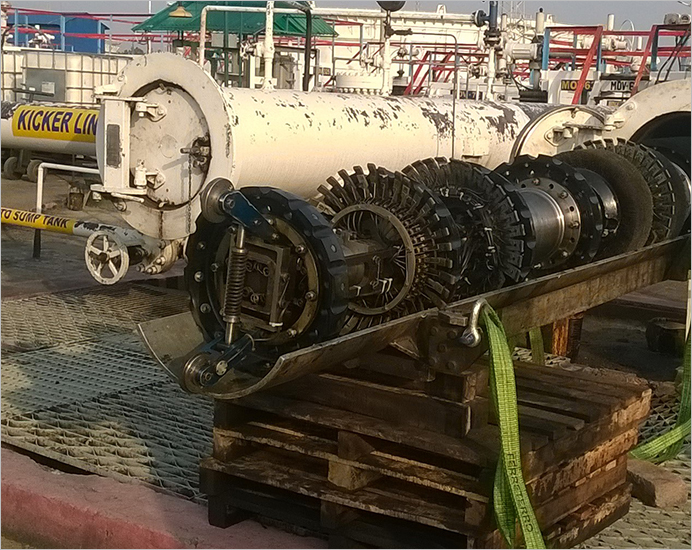

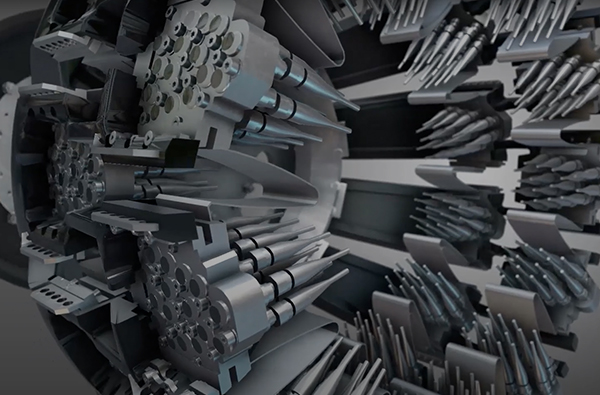

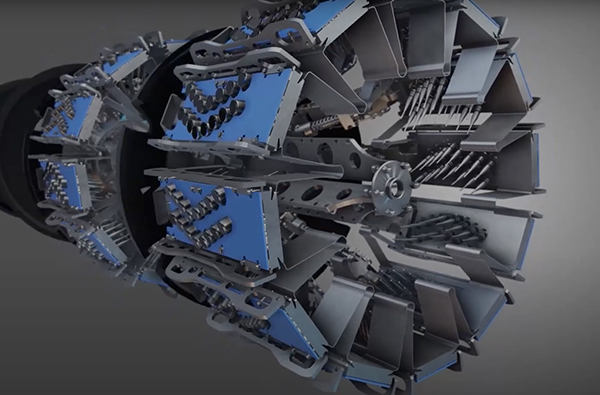

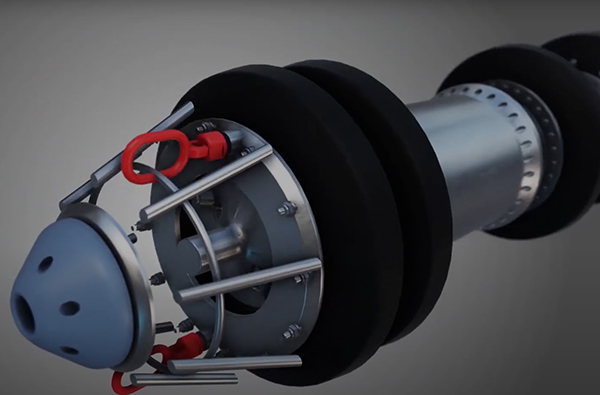

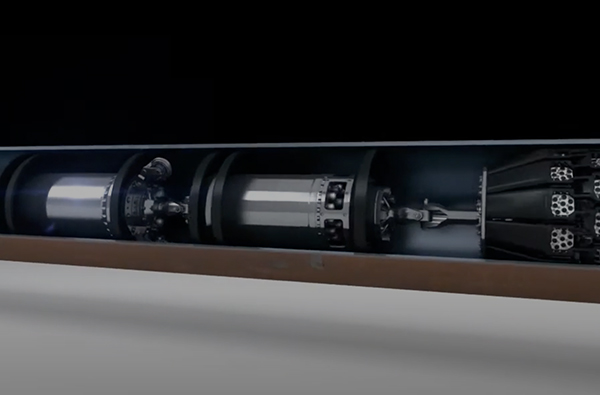

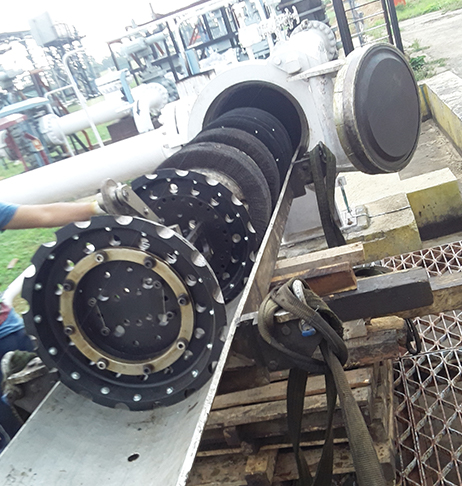

Gas Pipeline ILI by ART ScanTM - The ART ScanTM internal pipeline inspection solution performs “direct wall-thickness” measurements in high-pressure gas pipelines, giving the operator a more accurate depth measurement and providing them with the information required to carry out their integrity assessments with greater levels of confidence.